So I’m a bit of a LEGO enthusiast. This has led me to become very fascinating by cool building techniques. And like every other LEGO enthusiast, I’m well acquainted with the SNOT building system (Stud Not On Top). But there is one particular SNOT technique that has a bit of debate associated with it. Specifically, its status in terms of legality. As you know, there are many building techniques that are considered “illegal” and would never appear in official sets. There are many conditions that make a building technique illegal, but the main points are that they generally form connections that are unstable and can lead to damage to the bricks themselves. There are often connections that, in a pinch, look like they make sense, but they’re actually stressing the elements in a certain way.

I do want to preface this by first saying that I will be conducting my own independent data collection prior to going online and doing research on what other people have said about this topic. I want to be able to make my own conclusion and see how it compares to that of others. I will, however, be referencing official LEGO documents such as patents and internal employee documentation.

The potentially illegal build I want to discuss today is the plate-between-studs SNOT technique.

This consists of a LEGO plate attached perpendicular to another brick via clamping the plate between two studs.

There aren’t many official sources that directly discus build legality, but most LEGO builders will reference this document made by legendary LEGO designer Jamie Berard. It’s a presentation showing some illegal building techniques and explaining why they are illegal. One thing that should be noted is that legality can be revoked. Just because a technique was once used in the past in an official set doesn’t guarantee it will be a legal build within today’s guidelines. Given that this document is pretty old, it might not be a 100% accurate source.

You’ll notice on page 23 of the presentation, the plate-between-studs (I’m going to abbreviate this into PBS from now on) technique is explicitly stated to be an illegal building technique. The description simply states that the dimensions don’t line up. Further clarification is given in this video by another legendary former LEGO designer: Tiago Catarino. I want to make a disclaimer that although he used to be a member of the LEGO Group, his video was posted well after he left the company. So we cannot treat it as an official statement by the LEGO company. But generally speaking, he is still a pretty trustworthy source.

In his video, he explains why the PBS technique is harmful to LEGO bricks and gives a visual representation for how the bricks are affected.

This is quite a powerful visual as it shows the brick clearly in stress. However, in the same video, he claims the PBS technique is only illegal for plates with studs on top. Tiles, or smooth LEGO plates, are exempt from the rule and are allowed to be placed in a PBS formation. As a matter of fact, this is backed up by the fact that numerous recent LEGO sets from the past decade use this “TBS” (tiles-between-studs) technique. The examples given in his video include the LEGO Empire State Building (2019), the LEGO NASA Apollo Saturn V (2020), and the LEGO Creator Expert Haunted House (2020). But earlier examples also exist dating far back as 1978 in sets such as the LEGO 375-2: Castle set.

Tiago claims that TBS is allowed since on a microscopic level, tiles are slightly thinner than plates. And this difference is the exact tolerance needed for tiles to snuggly fit between two studs without constituting an illegal build.

I plan on testing that. Because I don’t buy it.

Let’s start off with some data. First, we need to define the difference between nominal measurements and actual measurements. Nominal measurements refer to the intended dimensions of an object (the LEGO brick). LEGO works off of a system. LEGO builds operate under the assumption that these nominal dimensions apply. For example, a 2 by 4 brick is supposed to occupy a 16 mm wide and 32 mm long space. But in actuality, bricks are actually shorter by 0.1 mm on each end to reduce friction so that when two bricks are placed next to each other they rub too hard. So the actual dimensions are 15.8 mm and 31.8 mm respectively. But when connected to the brick and stud system, everything is still at the correct nominal distance apart.

Notice how if pressed together, the two bricks are 31.6 mm thick (0.1 mm shaved off the two sides of each brick means 0.4 mm total from the intended 32 mm) but if measured while the two bricks are connected within the stud system, the measurement reads 31.8 mm. This is because the stud system dictates the correct nominal distance between two bricks.

This diagram from https://www.cailliau.org/en/Alphabetical/L/Lego/ also illustrates it quite well.

According to various hobbyists and fan wiki pages online, the accepted nominal height for a LEGO plate is 0.32 mm. This can be implied by the official patent of a LEGO brick found on espacenet, since a plate is 1/3 the height of a brick (0.96 ÷ 3 = 0.32).

So let’s do some quick maffs using the rest of the information presented in the diagram along with commonly accepted knowledge revolving the LEGO system. The center distance between two studs must equal the nominal length of a 1 by 1 brick by definition, which is 0.8 mm. So the minimum distance between the circumference of two studs would be 0.8 mm minus the diameter of a stud, which is shown to be 4.8 mm. This means the gap distance between two studs would be 0.32 mm. Wait? 0.32 mm?? That’s exactly the height of a plate. So by this logic, shouldn’t both PBS and TBS be completely legal?

Well, let’s take a look at the actual measurements of LEGO bricks.

Let’s start off with the distance between two studs. Using a digital caliper, I measured the outer distance from opposing ends of each stud to be around 12.88 mm with a 0.01 mm wiggle room.

I then measured the diameter of a single stud and found it to be roughly 4.88 mm, which is a significant larger than the listed 4.8 mm in the patent. This means the calculated distance between the circumference of two studs is 3.12 mm (under the assumption that the stud is a uniform circle). Let’s be generous and say at the very most, a 3.13 mm gap. Far less than the 3.2 mm a plate is supposed to be.

I also did a direct measurement between the studs, which confirmed my previous findings. I didn’t want to just rely on this measurement since my caliper isn’t designed to optimally measure these kinds of scenarios. Not enough contact area.

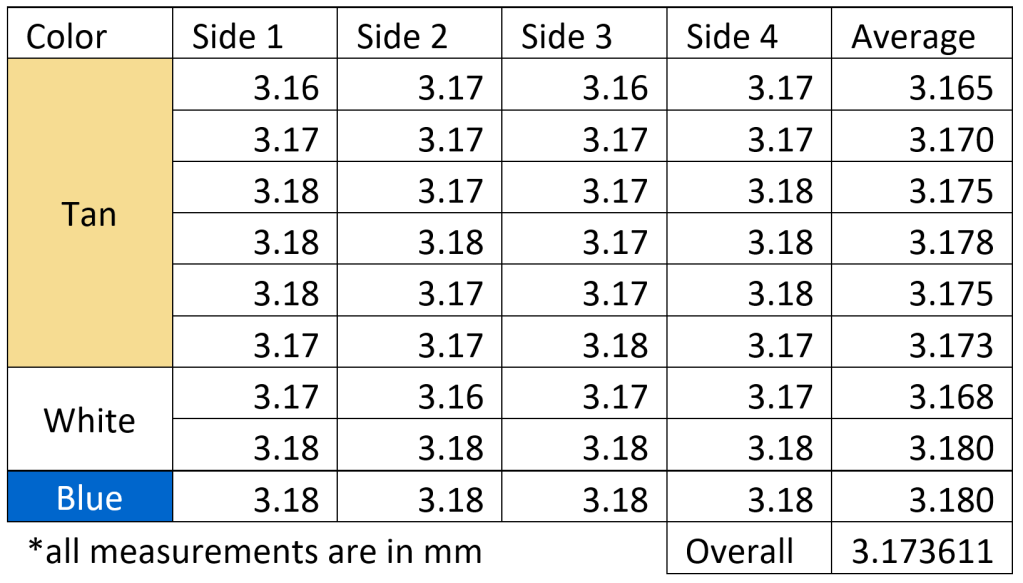

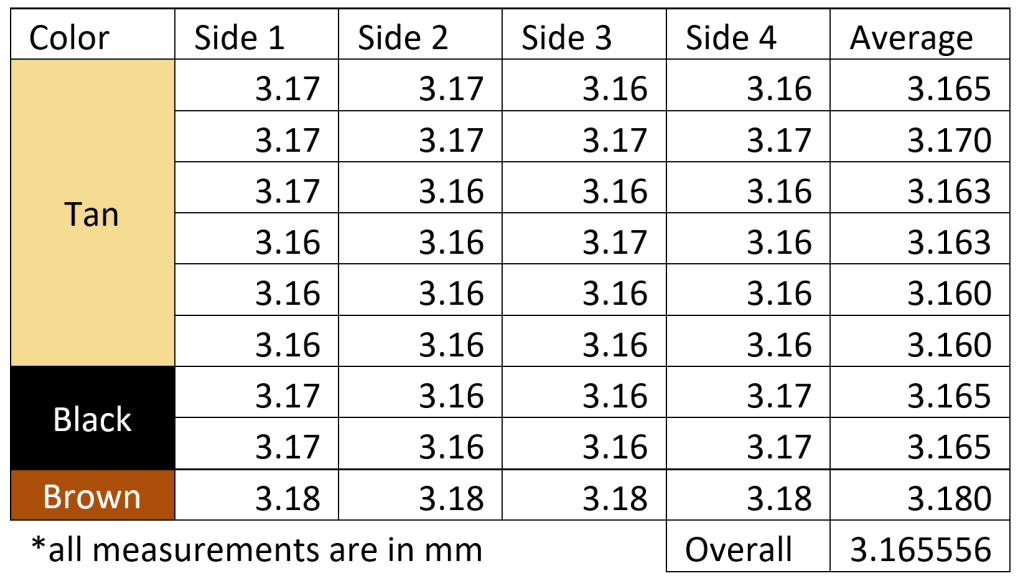

I then used my digital caliper to measure the sides of several different 2 by 2 LEGO plates. Most of them were tan colored plates I had from my LEGO Titanic set, but I also tested a few white and blue ones to ensure there was no significant manufacturing bias with the colors.

With a couple more miscellaneous undocumented random sampling measurements of other plates in my collection, the general conclusion is that LEGO plates have an actual thickness closer to 3.17 mm with a 0.01 mm range of error. Now this is very interesting to me for several reasons, but let’s focus on just the number itself for now. So next let’s measure some LEGO tiles.

At first glance, you might say Tiago was right. The tile bricks do appear to be “microscopically” thinner. But let’s rewind a bit. These measurements are in MILLIMETERS. The difference between the final averages of the tiles and plates is only 0.008 mm. My sample size is too small for this difference to be meaningful given that my caliper is only accurate down to 1 thousandths of a millimeter. So what does this mean? After all, further undocmumented smapling of other tiles led me to find a lot of them even had a 3.18 mm thickness across the board. We appear to be leaning more towards the idea that tiles and plates are supposed to be identical in height. But I’m not going to rule out the possibility that the 0.008 mm thickness difference exists. entertainment.howstuffworks.com states LEGO bricks have a manufacturing tolerance of 0.002 mm (the webpage lacks sources so take this with a grain of salt. Wikipedia claims typical injection mold tolerance is less precise). And my personal experience with LEGO bricks over the years confirms the quality of their products. I definitely believe they are capable of such precision.

But here’s the thing: NEITHER of the bricks are even close to clearing the 3.13 mm gap that I measured earlier. Because let’s be honest, physically measuring the bricks is more of a distraction. Feast your eyes on this:

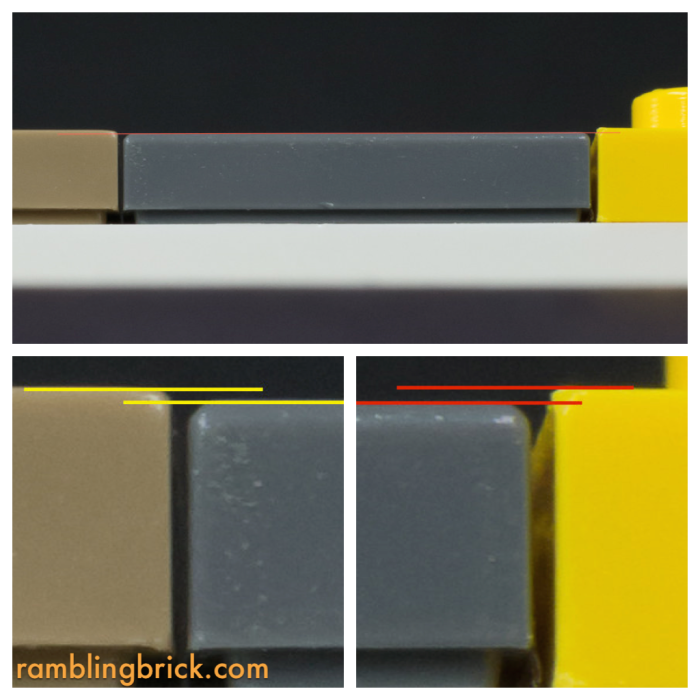

Yep. That’s right. Both plates AND tiles will bend a LEGO plate when using the PBS/TBS technique. Without doing any measurements at all, we can clearly see that the bottom plate is under stress when the tiles are inserted as such. However, this is where I noticed something interesting. The picture on the right appears to be significantly more curved than the one on the left. This does suggest that intrinsically, there is a difference in height for tiles and plates.

At first, I wondered if this is due to the stud interference. Obviously you can tell from the picture below that the height of the stud interferes with the plates being fully inserted into the bottom plate.

This unbalance means potentially, the plates could be at a slight angle when not completely perpendicular to the bottom brick. This will obviously lead to further deflections and bending in the bottom brick. So what if we offset the bricks so that the studs do not interfere with each other?

I recreated the build but instead of using 2 by 1 plates, I used 3 by 1. I then offset them so that the plates are perfectly centered along the bottom brick. This ensures all the plates sit flush against the surface of the bottom plate. I even build a little jig with a wall to help with allignment.

In addition, I also made one using 2 by 1 jumper plates. Because I was curious how they fit when it comes to height classifications.

This gives me a total of four arches:

Setting them on the table and then measuring the distance from the table to the tip of the arch lets us determine which one has the greatest bend.

From curviest to least, we have:

2 by 1 plates at 3.31 mm

3 by 1 plates at 3.3 mm

2 by 1 jumpers at 2.56 mm

2 by 1 tiles at 2.23 mm

So… it appears tiles are literally just built different. They cause a significantly smaller curvature on the base plate for some reason, which I can only attribute to the supposed microscopic difference in height that multiple sources have claimed.

This is the part where I hop online and see what other people have to say about the issue. I did a bit more digging and found this blog post from 2017 on the website The Rambling Brick. Here, the author actually got a chance to interview Jamie Berard, the guy who wrote the illegal building techniques presentation. He reasserts that tiles are indeed microscopically thinner by a degree. The author of the blog later uses a macro lens camera to photograph a tile next to a plate.

The very general consensus across several other online discussions also concludes that tiles between studs is ok (sometimes simply from the fact that people see it in official sets).

At this point, it’s not about trying to confirm whether tiles are thinner than plates or not. Because the fact still remains is that there is visible stress on the LEGO brick when the TBP technique is used. So the question that remains is, should TBS be banned as an illegal technique? And if not, is it hypocritical to ban PBS? Do either of them need banning? We now turn our heads to material properties.

The yield tensile strength is how much stress a material can take before it will no longer recover and return to its original shape. The idea is that LEGO bricks can bend a little bit but still be undamaged as long as we do not bend it past its yield point.

LEGO bricks are typically made of acrylonitrile butadiene styrene (ABS). The yield stress of ABS is at least 29.6 MPa according to omnexus.specialchem.com. We are going to be conservative and go with the lowest end. I have no doubt that LEGO actually uses high grade ABS, probably way higher than that, but since I cannot confirm that, I’ll stick with 29.6 MPa. https://www.matweb.com/ also has data for extruded ABS, which has significantly lower yield strength, but we know for a fact that LEGO are made through injection molding so we can ignore that. (The non-extruded data values they had for ABS was also around 29 MPa). The lowest listed Young’s modulus is 1.79 GPa. This will also be important later.

Let’s use the 16 by 2 plate as an example since we already have its dimensions and information on its bend. If we look at the structure, you’ll notice it can be essentially simplified as a beam that has a constant bending moment along its length.

The bending stress is thus determined by the formula:

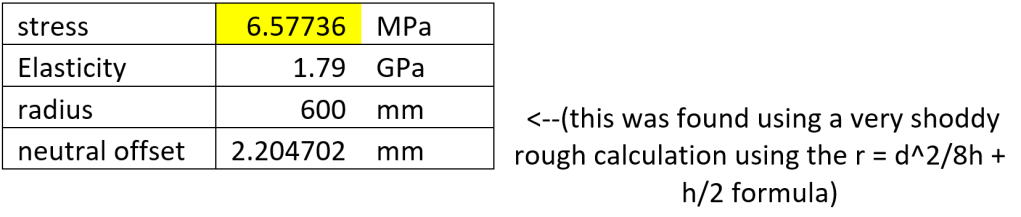

σ = Ey/R

where E is Young’s modulus, y is the distance from the neutral axis, and R is the radius of curvature. We have the Young’s modulus from online sources as mentioned earlier. The position of the neutral axis can be calculated easily since the cross section of the plate is relatively simple. I will ignore extra geometry such as the studs and clutch tubes to simplify the system. Below is the formula I used along with a drawing of the cross section I was drafted.

yn = (A1*y1 + A2*y2)/( A1 + A2)

where A1&2 are the areas of the individual rectangular segments and y1&2 are the distance the centers of those rectangles are from the origin line. yn thus is the location of the neutral axis in respect to the chosen origin. This calculates out to a value of 2.204702 mm from the bottom of the plate.

We now have all the values we need to find the stress. Organized below is a table of all the values. We get a final answer of roughly 6.6 MPa.

So at the very most, the plate experiences 6.6 MPa of stress when bent from PBS or TBS build. This is significantly less than the 29.6 MPa yield stress that ABS plastic is able to handle. This is even less than the minimum yield stress of extruded ABS plastic (which we previously established doesn’t even matter since LEGO bricks aren’t extruded). So in other words, the plate is in NO danger of any sort of permanent deformation or breakage… at least it seems at first.

If I may redirect your attention to another piece of information also given on the https://omnexus.specialchem.com/ page for ABS plastic. Take a look at the elongation at yield value. This value is in the form of a percentage and refers to how much a material can deform before achieving permanent deformation. On the website, it states that ABS has a range between 1.7% and 6%. This means in worst case scenarios, the plastic will be damaged after a 1.7% change in deformation. Now I will admit this is a rather finicky way to determine acceptable ranges of flex. Since the elongation at yield value typically applies to linear elongation and is found through tests where a rod is pulled apart. I don’t know how this applies to a scenario where two cylinders are being flexed away from each other like in the case of a plate being wedged between two studs. Using prior measurements, two studs would need to increase separation distance by roughly 1.6% to accommodate for a ridged 3.17 mm wedge ((3.17 – 3.12) ÷ 3.12) = 1.6%. This is really cutting it close. But the wedge in this case is a LEGO brick which can also deform. So in actuality, the deformation for any given piece is less than 1.6% most likely.

At the end of the day, it isn’t up to me to decide whether a LEGO technique is legal or not just based on some rough material property calculations. Just because a certain action won’t “technically” damage or deform the LEGO bricks doesn’t mean it is suitable for a stable build in an official LEGO product. I simply wanted to confirm some of the statements given by the LEGO Group regarding the legality of PBS and TBS building techniques. And my conclusion is as follows: both tiles between studs and plates between studs will cause noticeable bend in a LEGO brick if used in excess on a thin piece. Tiles do appear to be thinner than plates by a small amount that I am unable to fully determine without better equipment. But I argue that the difference is actually negligible in the grand scheme of LEGO building. Given that official examples of TBS in official sets typically use the technique in moderation, I argue that it should be reasonable to use PBS as well. The only problem is that PBS is harder to use given the stud interference causing unstable connections. Jumper plates or other types of LEGO bricks with a center stud arrangement is needed to ensure flush connections if trying to build with PBS. This makes it understandable why official sets stray away from using the technique. While I don’t want to make any statements on whether PBS should be made legal or not, I think it should at very least be decriminalized. Think of all the poor hobbyists and builders be harassed constantly online in the comment sections whenever they reveal a build that contains PBS.

In conclusion, don’t feel bad about placing LEGO plates between studs for SNOT buidling. You aren’t in real danger of damaging your bricks probably, not any more than a tile piece would. Especially since you will hardly ever need to repeat the technique that many times on a single base piece. And even if that was the case, I want to note that all four of the 16 by 2 plates I experimented on are all perfectly fine and in their original shape despite me having left them bent overnight.

Leave a comment